欢迎浏览郑州四棉纺织有(yǒu)限公司官网!

服務(wù)热線(xiàn):0371-60862710

ABOUT US

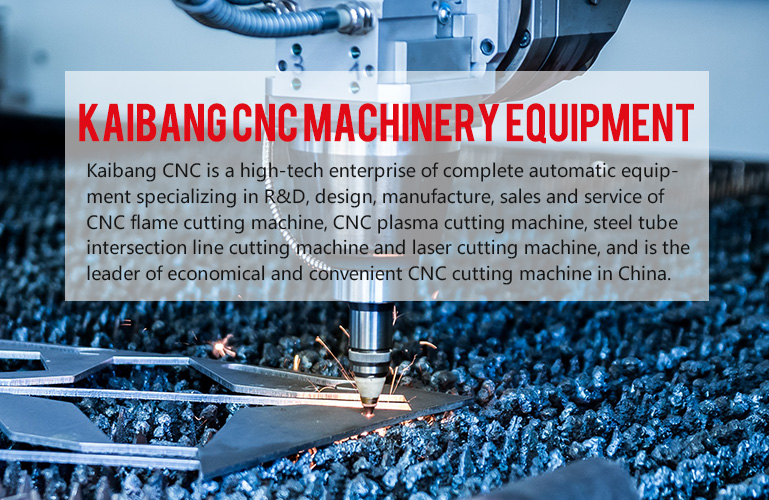

Kaibang CNC is willing to work together with friends from all circles to seek common development and create a better future

With production base in Luoyang, the ancient capital of the 13 Dynasties with beautiful environment and pleasant climate, the company was founded by a well-known professor and doctoral supervisor of electromechanical science in Huazhong University of Science and Technology, China. Since its establishment, it has adhered to the principle of "people-oriented, scientific and technological innovation". After more than 10 years of experience in research and development, sales and production, it has become a large-scale CNC cutting machine production enterprise in Central China with strong technical strength, complete varieties and specifications and large sales volume.

Perfect Quality Management System

Advanced Production Technology

Perfect Products and Services

Products sell well in China and are exported overseas

PRODUCTS

Kaibang CNC is willing to work together with friends from all circles to seek common development and create a better future

Service Hotline

0086-189-3790-7426

Service quality is the lifeline of any enterprise and the cornerstone of its survival. It determines the future of the enterprise. Good service quality can enhance the competitiveness of the enterprise and consolidate its market position, otherwise, the enterprise will gradually decline after losing the trust of market.

WHY CHOOSE US?

The company focuses on the construction of quality system and environmental system safety, and has passed ISO9001 quality management system,

ISO14001 environmental management system and OHSAS18001 occupational health and safety management system certification

Strong R&DCapabilities

A professional and experienced design team provides you with professional solutions, and is good at analyzing customer needs and tailoring solutions for customers.

Advanced Production Equipment

It has a professional research and development, operation and maintenance team of CNC equipment and a large-scale CNC equipment parts processing base. The company has introduced two large five-sided gantry machine tools with a value of 15 million Yuan, and has complete machining, sheet metal and painting process.

Superior Quality Assurance

All products are equipped with accessories from first-line regular factories, some of which are imported from Germany, Italy, Japan and other western countries. The engineering quality and construction period are guaranteed from the source, reducing the intermediate price difference, and creating a cost-effective project.

Considerate After-Sales Service

The professional after-sales team provides you with timely and efficient problem solutions. If you encounter any problems during product installation and use, you can contact us as soon as possible. Customer

service hotline: 0086-18937907426

NEWS

Kaibang CNC is willing to work together with friends from all circles to seek common development and create a better future

Navigator

Contact Us

Liaison :Manager Bai

Mobile :18937907426

Email:cnzztex@126.com

Address:Xiangquan Village, Xianglushan Town, Yiyang County, Luoyang City

Powered by:300.cn